Artificial Intelligence in Manufacturing: Types, Challenges, and Uses

Artificial Intelligence in Manufacturing

AI implementation can make robots smarter, reduce the downtime of machines, and increase productivity. Such high adoption rate of industrial robots in manufacturing plants is expected to drive the growth of the artificial intelligence in manufacturing market in Asia Pacific. Manufacturers that adopt Generative AI are see significant gains in efficiency, productivity, and innovation. However, it is important for manufacturers to ensure that they are using Generative AI ethically and responsibly, and to address any potential issues related to job displacement or bias.

The integration of AI in the manufacturing market has brought significant advancements to warehouse management. From inventory optimization to streamlined order fulfillment, AI-powered manufacturing and ML in manufacturing solutions are transforming warehouses, making them more efficient and cost-effective. Manufacturing plants, railroads and other heavy equipment users are increasingly turning to AI-based predictive maintenance (PdM) to anticipate servicing needs. An airline can use this information to conduct simulations and anticipate issues. Safeguarding industrial facilities and reducing vulnerability to attack is made easier using artificial intelligence-driven cybersecurity systems and risk detection algorithms.

Design and Production With AI

AI steps in as a cognitive assistant, providing real-time insights, recommendations, and data analysis. Workers can make informed decisions swiftly, leveraging AI’s computational power to handle data-intensive tasks. AI-powered quality control doesn’t stop at identifying defects; it fosters a culture of continuous improvement.

This metric will help manufacturers train deep learning models and fix potential problems that could arise before they’re in danger of manifesting into something worse. The company and Google are using AI algorithms, cloud-based analytics, and computer vision to improve shop floor productivity. During the former, a set of specific additives are melted and heated up in a furnace to a temperature sufficient for creating glass. Then comes the cold phase where already molten glass is channeled to the special metal alloy plates called bushings. To become fibered, glass has to pass through holes in bushings (with an average diameter of about micrometers). The break of a fiber occurred when the glass was running through these holes and the pulling force was applied to it.

Benefits of AI in Manufacturing

AI’s machine learning algorithms excel at recognizing patterns, making them ideal for real-time defect detection. Cameras and sensors can monitor production lines, and AI can swiftly identify deviations from the norm. This leads to prompt corrective actions, minimizing waste, and maintaining high-quality standards.

- First, AI increases productivity and efficiency by automating routine operations and freeing laborers for more challenging and innovative work.

- This enabled the most efficient exploitation of their ships as well as improved brand image and client satisfaction.

- After learning this information, the team tweaked the leaching process — which increased yield by 3.7%.

- This leads to faster order processing, reduced errors, and improved customer satisfaction.

- Industrial units have already begun to deploy AI and predictive tools powered by ML that are able to predict when equipment will need routine maintenance.

AI is being used in many different ways across a range of different industries — from agriculture to transportation, from healthcare to hospitality. Let’s take a look at how AI is already impacting manufacturing processes, and how it may shape the industry going forward. The initial implementation of AI can be expensive, especially for small companies and startups taking into account data acquisition and engineering costs. However, a lot depends on the problem a manufacturer wants to solve with the help of artificial intelligence. If the in-house team needs to develop AI systems ab initio, the price will get higher than for consulting a narrow-specialized expert.

Manufacturing Outlook Survey

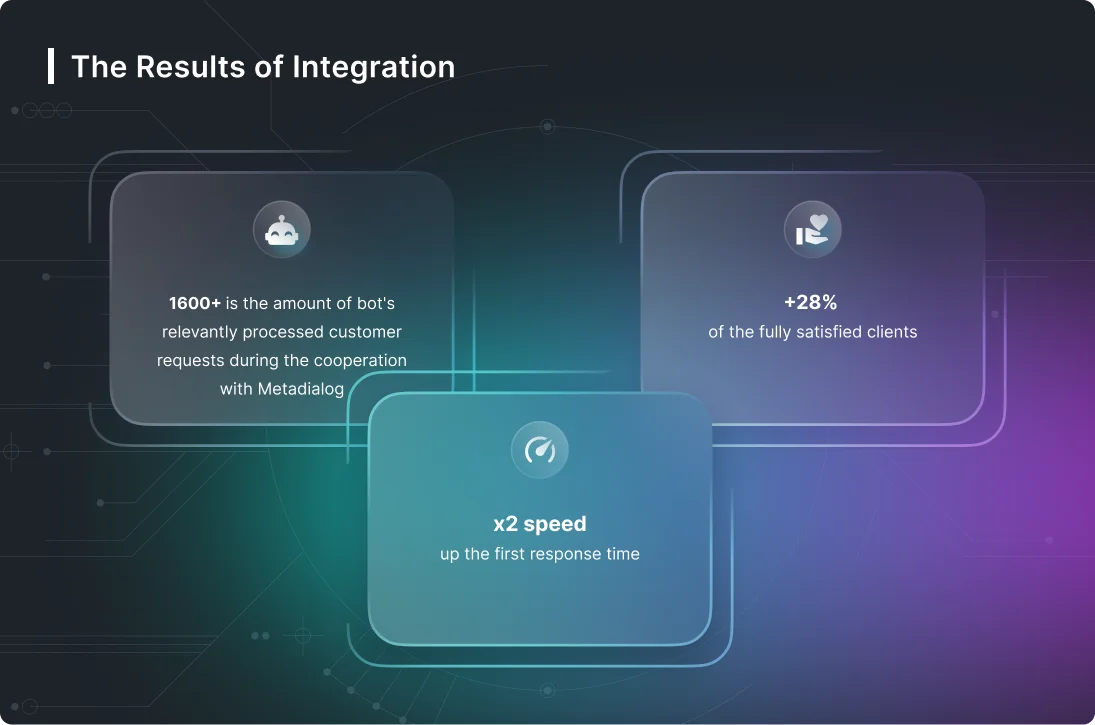

Read more about https://www.metadialog.com/ here.

Exclusive: ChatGPT-owner OpenAI is exploring making its own AI … – Reuters

Exclusive: ChatGPT-owner OpenAI is exploring making its own AI ….

Posted: Fri, 06 Oct 2023 07:00:00 GMT [source]